Program Management

The company was embarked on a strategic semi-conductor development program, consisting of more than 70 person-year involvement with very limited program planning capability. The existing program manager felt overwhelmed by the situation, burned-out and resigned.

Problem description

All the engineers have undisputed skills and knowledge to complete their duties.

The semiconductor development must follow a clear path prior to “taping out”, which refers to delivering a complete and verified dataset to the production factory. A tooling, expensive in cost and lead time, is produced with the delivered dataset, which hinders any possibility to iterate on the features and performance of the product.

Solution delivered

Agile program methodology was used within the boundaries of a careful waterfall structured time-cost constrained program. The major milestones have been set and agreed upon. A tight weekly follow-up was set to closely follow-up on the progress. Meanwhile, a monthly steering committee kept all stakeholders transparently informed about the risk assessment and mitigation all along the program, until successful delivery.

Result

The initial time-cost budget was reassessed and approved by all stakeholders.

The program was delivered according to this updated budget.

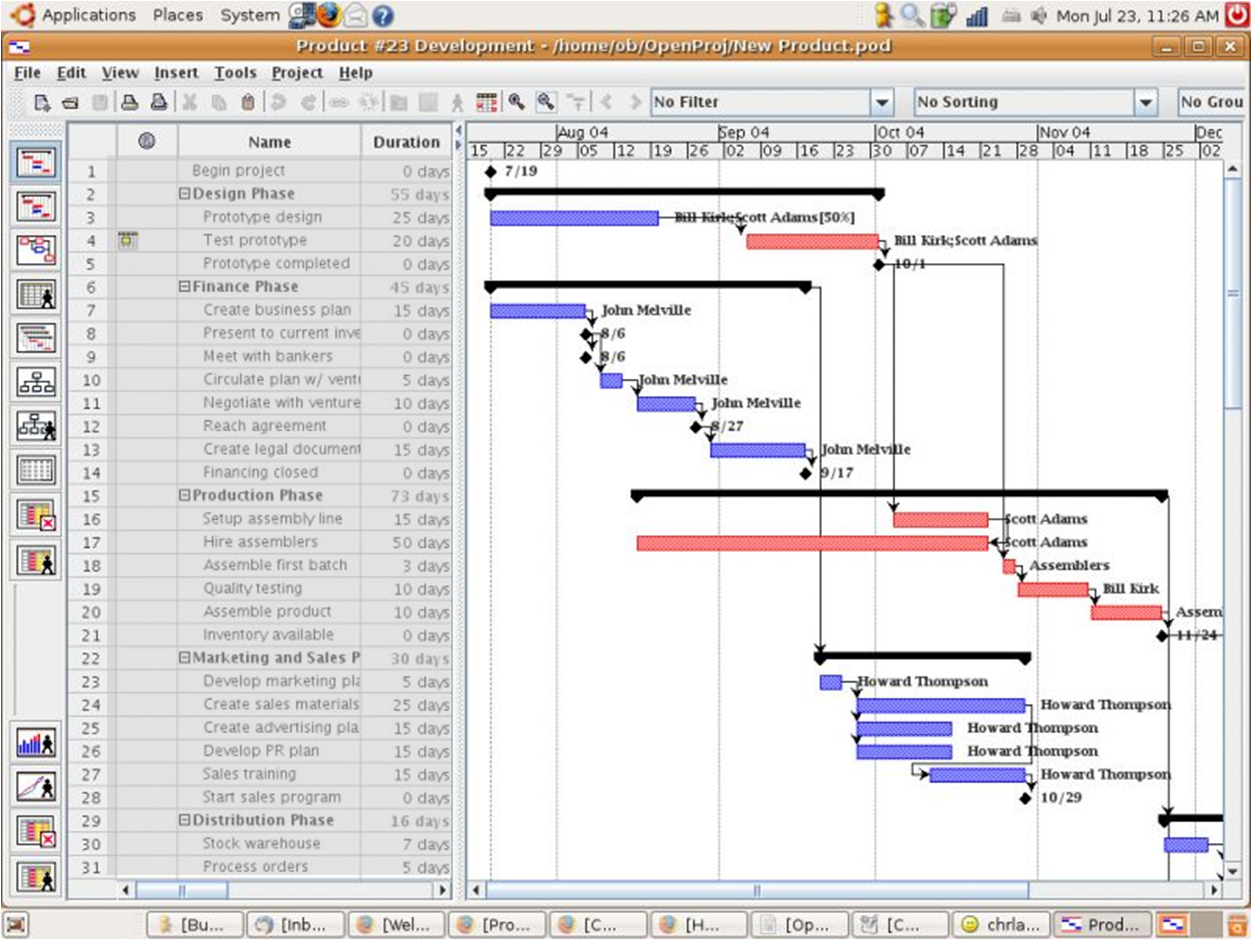

Illustration

Semi-conductor programs are always strictly covered by non disclosure agreements. We take great care to enforce this confidentiality, being aware that it's a critical part of our client's competitive advantage.